System introduction

The collection of garbage and soiled clothing and clothing in the hospital through the pneumatic conveying pipeline is a modern garbage transportation and collection mode that implements the fully closed, compressed and containerized collection and transportation of garbage; After the system is applied in the hospital, it will improve the overall garbage collection efficiency in the hospital, eliminate the secondary pollution of garbage, dirty clothes, clothing and other pollutants to patients, staff and the environment, and is an important infrastructure for the construction of a modern green hospital.

Technical description

1. Stainless steel garbage and clothing riser: specification: 500mm, material: SUS304 stainless steel, thickness: 1.5mm, flange socket type connection.

2. Garbage horizontal pipe: specification: 500mm, material: Q235B, thickness: 6mm, connected by welding.

3. Linen horizontal pipe: specification: ø 500mm, material: SUS304 stainless steel, thickness: 4mm, connected by argon arc welding.

4. Garbage pipe elbow and tee: specification: 500mm, material: Q235B, thickness: 8mm, connected by welding.

5. Elbow and tee of the clothing pipe: specification: ø 500mm, material: SUS304 stainless steel, thickness: 6mm, connected by argon arc welding.

6. Introduction to garbage bedding:

The door is composed of stainless steel door panel and door frame

Door panel and door frame are made of SUS304 stainless steel plate

The bolt of the entry door is firmly installed on the input station. When the entry door and the input station are connected, the slot connection is made into a pull type, so that it can be adjusted to be flush with the wall after installation to make it beautiful and standard.

The access control card swiping interlock system is adopted for the entrance of the floor, which only allows the entrance of a single floor to ensure the safety of personnel.

It is equipped with voice prompt function and panel display function to prompt the staff to shut down in case of overtime.

7. Garbage storage section: specification: 500mm, material: Q235B, thickness: 6mm, vertical garbage temporary storage device, height > 800mm, automatic garbage detection

8. Clothes storage section: specification: ø 500mm, material: SUS304, thickness: 4mm, vertical clothing temporary storage device, height > 800mm, automatic detection of clothing quantity

9. Garbage discharge valve: specification: 500mm, material: Q235B, thickness: 6mm, garbage discharge control

12. Cloth discharge valve: specification: 500mm, material: SUS304, thickness: 4mm, to control the discharge of clothing

13. Garbage separator:

Separation principle: cyclone centrifugal force, gravity

Material: Q235B

Disposable garbage: 60~80m ³/ h

Large operating air pressure: ≥ 45kPa (negative pressure)

14. Server collector:

Material: Q235B

Volume: 2.3m ³

15. Fans and motors

Power: 132kW

Rated flow: ≥ 8m ³/ s

Rated wind pressure: ≥ 12kPa

Category: Centrifugal

Connection mode: series connection

16. Air compressor system:

Power: ≥ 15kw

Operating output pressure ≥ 0.6 ~ 0.85Mpa

Air tank capacity: ≥ 0.6m ³

17. Electrical control system:

Main control system: vertical control cabinet

Main control software: system control software

PLC control system: including PLC system, communication system, access control system, etc

Central control computer: power supply, memory, hard disk, display, keyboard and mouse, etc

Central control console: 1200 * 600 * 600

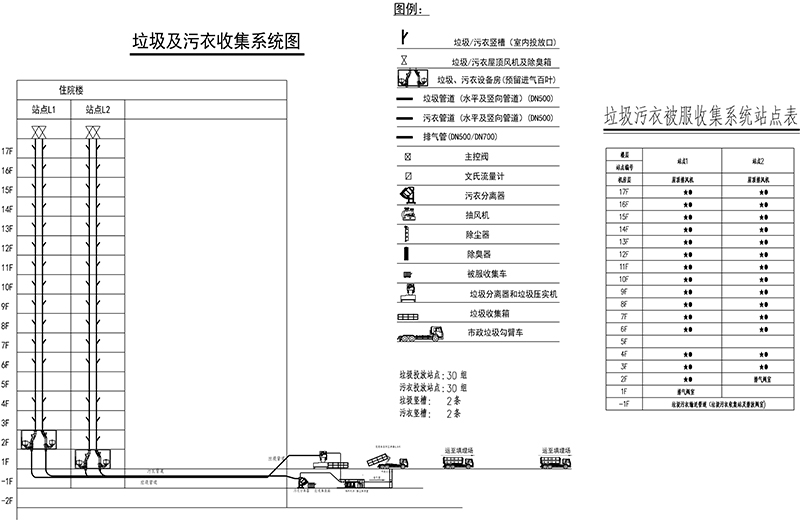

System diagram

Garbage and clothes dropping port

Outdoor air inlet and garbage outlet

Horizontal pipeline in basement

Garbage station