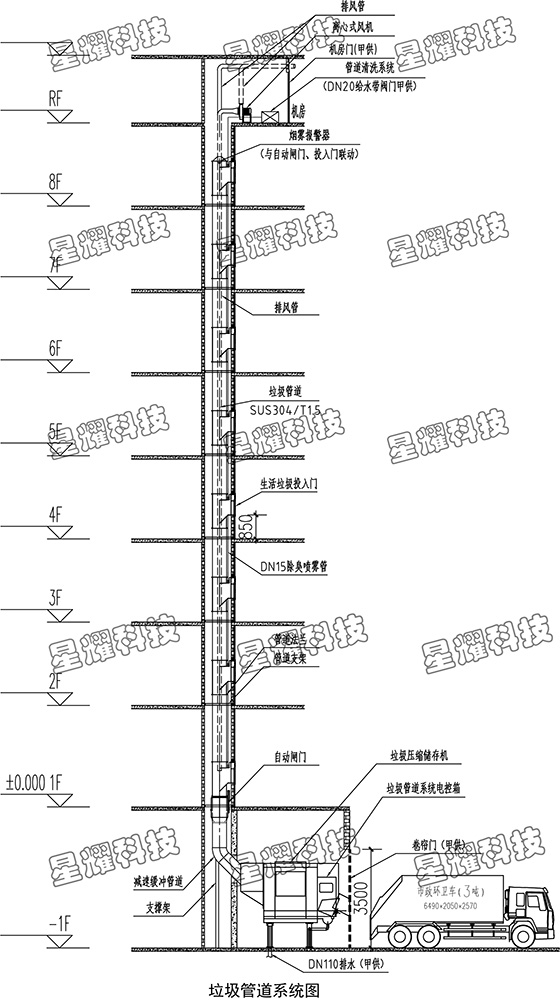

System introduction

1. Garbage pipes are 304 stainless steel pipes installed inside or outside the building.

2. After the installation of garbage pipes in high-rise buildings, people can directly deliver domestic garbage from upstairs to the pipes, and from the pipes to the garbage collection room. It is conducive to building energy conservation and time saving, reducing bacteria breeding, and improving environmental health.

3. Especially in hospitals, the current situation of the hospital is that elevator resources are tight, and the transportation of domestic garbage takes up elevator resources, takes a long time, goes upstairs and downstairs, and is inefficient.

4. The garbage pipeline is equipped with an exhaust system. When the inlet is opened, the exhaust system works to generate negative pressure at the outlet of the inlet to prevent odor diffusion.

Technical description

1. Stainless steel main pipe: specification of ø 600mm or ø 500mm, material of SUS304 stainless steel, thickness of 1.5mm, and flange socket connection.

2. Garbage compressor: storage capacity 6m ³~ 14m ³ (after compression)

Inner cylinder material: stainless steel SUS304 plate, 4mm thick

Equipment shell material: national standard Q235A plate, 1.5mm thick

Main motor: three-phase asynchronous motor; Number of poles: 4 poles; Rated voltage: 380V; Rated speed: 1450rpm;

3. Pipeline cleaning equipment: this equipment is located above the main domestic garbage pipeline. The motor and reducer are used to drive the lifting brush. The brush is connected to the inner pipe wall, and the upper and lower limit switches are set. A cleaning agent bucket is added above the brush. During flushing, the agent is automatically added and the cleaning agent is sprayed.

4. Centrifugal fan:

Fan parameters: power 3kW, voltage 380V, frequency 50HZ

Air volume 2800m ³/ h

The equipment realizes joint control, and automatically operates when the input door is opened, without manually controlling the switch.

5. Exhaust pipe: exhaust pipe: ø 219 stainless steel pipe, thickness not less than 1.5mm

6. Garbage input door:

The door is composed of stainless steel door panel and door frame

Door panel and door frame are made of SUS304 stainless steel plate

The bolts for the entry door are firmly installed on the input station. When the entry door and the input station are connected, the slot connection is made into a pull type, so that it can be adjusted to be flush with the wall after installation to make it beautiful

The door is opened up and down automatically and closed manually

7-inch LCD touch display

The input door is equipped with an infrared anti foreign matter probe safety device to prevent accidents. 7. Interlock system is used at the entrance of the floor, which is only allowed to be used at a single floor to ensure the safety of personnel

It is equipped with voice prompt function and panel display function to prompt the staff to close the overtime

7. Automatic gate: It is installed at the bottom of the garbage pipe and is normally closed, which can effectively prevent the odor in the garbage compression storage machine from spreading into the pipe; In addition, in case of fire in the building or in the garbage compression storage machine, the automatic gate can seal the pipeline, which can prevent the pipeline from producing chimney effect.

8. Electrical control system:

Main control system: vertical control cabinet (10.2 inch LCD touch display)

Software: PLC program control

Floor control system: smart card swiping authentication system (7-inch LCD touch display)

System diagram