Product Description

1. Working principle: rotary compression storage of drum spiral blades. The drum and blade are made of SUS304 stainless steel plate with good corrosion resistance. When the garbage enters the drum, the drum rotates to compress the garbage under the action of spiral blades.

2. When the municipal sanitation vehicle comes to clear and transport the garbage, the sanitation vehicle reverses to the wheel stopper, presses the equipment discharge button, the discharge door opens, the cylinder rotates, and the garbage is discharged to the sanitation vehicle under the push of the blade.

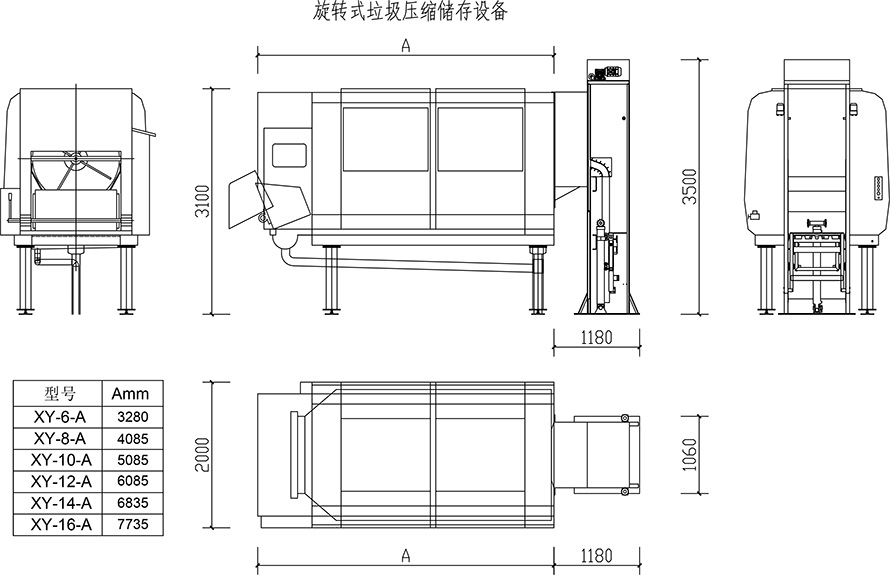

3. Model and specification

|

Model and specification |

Long mm |

Wide mm |

High mm |

|

XY-6-A |

3280 |

2000 |

3500 |

|

XY-8-A |

4085 |

|

XY-10-A |

5085 |

|

XY-12-A |

6085 |

|

XY-14-A |

6835 |

|

XY-16-A |

7735 |

4. Equipment dimension drawing

Technical description

1. Body material: Q235A material of the main frame of the equipment, and the thickness shall not be less than 5mm. The shell Q235 high tension plate is 1.5mm thick, and the surface is coated with anti-corrosion paint on both sides.

2. Drum material: equipment liner SUS304 stainless steel plate, 4mm thick.

3. Blade in cylinder: SUS304 stainless steel plate, 4mm thick.

4. Drive device: the motor reducer is mainly used to drive the drum to rotate with the chain gear. The motor is controlled by a high-efficient frequency converter, which can automatically control the speed of the drum, provide various protection methods that affect the normal operation of the equipment (such as overcurrent, overvoltage, overload safety protection, etc.), and effectively protect the normal operation of the equipment and the service life of each component.

Main motor: 380V, 50HZ, 3~5.5kw

Rotation number: ≥ 2R/min

Noise detection: ≤ 70db

Service life of equipment body: ≥ 10 years

5. Discharge device: door cover material Q235A Φ 1200mm thick 12mm

Cylinder pressure: thrust 1.5T

Oil cylinder motor: 380V 50HZ 1.5kw

The equipment has self-locking function

Lubricating device: adopt microcomputer fully automatic oil filling device and copper tube channel

6. Leachate collection tank: the waste water generated during garbage input is collected and discharged to the sewage treatment equipment through plastic pipes.

Material: SUS304 stainless steel plate

Sewage pipe: Φ 110mm PVC pipe

7. Input port: it is made of Q235A with a thickness of 5mm and placed above the equipment. It is equipped with an automatic oil cylinder lifting and closing device to coordinate with the equipment.

Drive mode: oil pressure drive

8. Elevator: It is set in front of the equipment and used with standard 120L, 240L, 260L and plastic garbage cans.

Drive mode: hydraulic lifting

Hydraulic motor: 380V 50HZ 1.5kw

Hydraulic oil tank: 60L

Hydraulic oil: 46#

9. Rack body: Q235A, 5mm thick, with two alarm lights on the top. The alarm lights flash during operation for prompt.

10. Electrical control system: Siemens PLC intelligent control system

Frequency converter Schneider

Electrical accessories - domestic and foreign

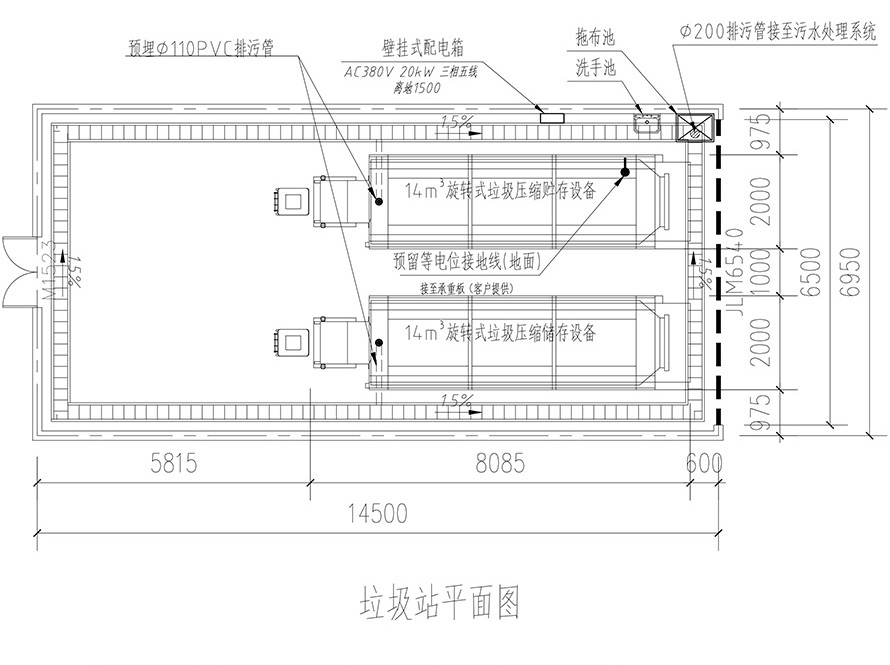

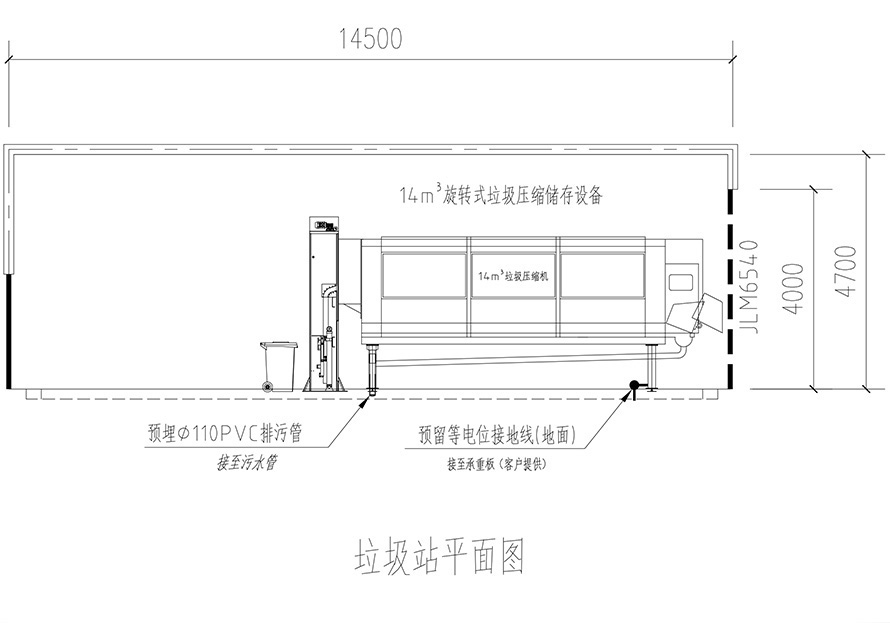

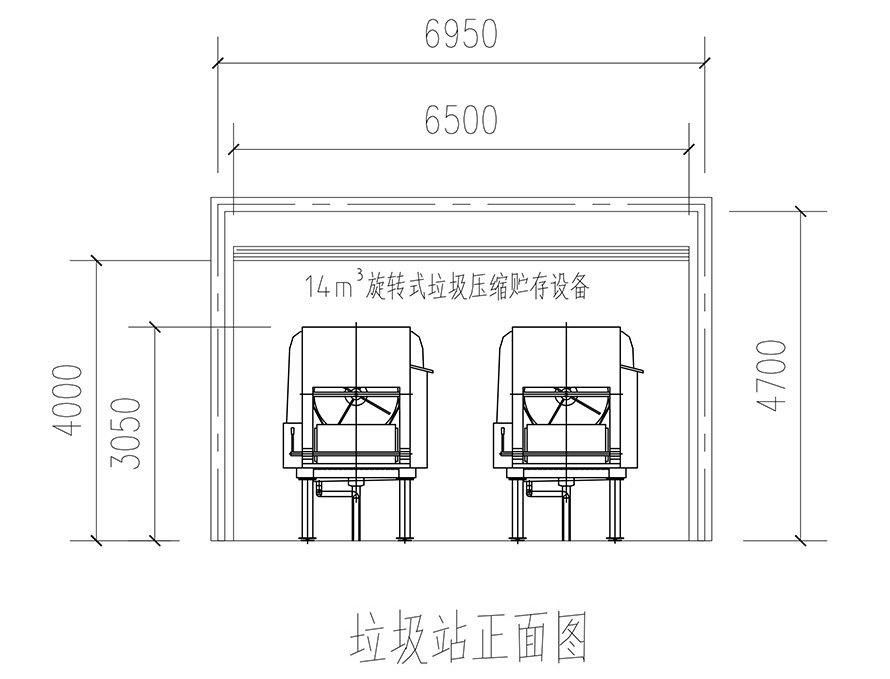

Site requirements

1. Strong horizontal foundation.

2. 10kW three-phase five wire power supply is reserved for single equipment.

3. The sewage pipe (ø 160) is reserved below one side of the equipment garbage inlet.

4. Reserve water supply and cleaning equipment and ground.

5. At least 0.5m maintenance space shall be reserved on both sides of the equipment.

6. Calculation formula of equipment energy consumption:

Monthly power consumption=total power of equipment * (10 seconds/60/60 * 30 days * times of opening the door/day)

Monthly electricity charge=monthly electricity consumption * electricity charge per kilowatt hour

Scheme map